Select your car

and see all the wheels that fit your car.

Wheels come in thousands of sizes and designs. What do these sizes mean and how are they used?

Below we’ll explain the most important terms.

wheel Diameter

The diameter of each wheel is expressed in the imperial unit INCH and is measured from opposite sides straight through the center of the wheel. The wheel diameter or inch size largely determines the appearance of the car. Not every inch size fits every car, often the larger the car, the larger the inch size can be.

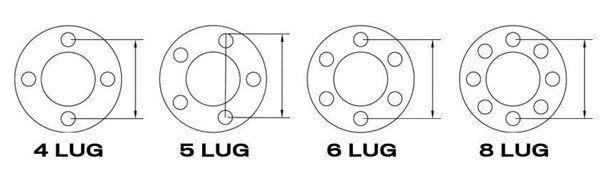

Bolt Pattern

A wheel is mounted with bolts or nuts on the vehicle's wheel hub. The bolt pattern on the wheel hub and thus the wheel, we call the pitch size. We express this using two numbers: the number of bolts and the distance of the holes between them. All even bolt patterns are measured from the center of the bolt hole to the center of the opposite bolt hole. Odd bolt patterns are measured from the center of one bolt hole to the extreme point of the opposite bolt hole. Picture below is for clarification. Lug in this case can be translated as 'hole', so 4-hole, 5-hole etc.

Wheel width

This size is also measured in INCH but written with the unit J. The J stands for the shape and width of the wheel bed and actually has nothing to do with the total wheel width. Because this term was so widely used to express wheel width, it was also taken into use for that purpose. 1J stands for 1 INCH. Unlike wheel diameter, wheel width is measured from the inside of the tire seat to the opposite tire seat. It is a common mistake to say that it is about the total width of the wheel.

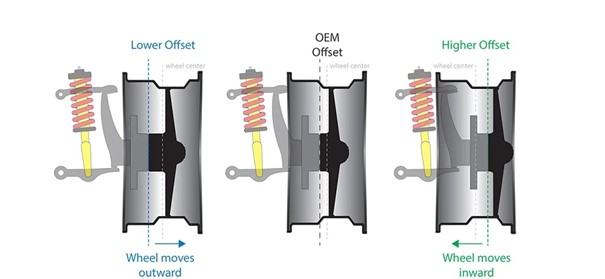

Offset

This is the trickiest piece of wheel measurement, but when properly explained and we use our logical mind it is quite simple. The offset of a wheel is expressed in ETs. ET is an abbreviation that stands for the German word "EINPRESSTIEFE" which literally means "INSIDE DEPTH". The ET value is determined by the position of the mounting surface of the wheel in relation to the width of the wheel. When a particular wheel has ET0, it means that the mounting surface is located exactly in the centerline of the wheel. If you move the mounting surface 10mm to the sight plane of the wheel, the same wheel has an ET value of ET10.

Wheel Fabrication

As a car enthusiast, you will probably know that there are several ways in which a wheel can be made. The average car enthusiast will then say, "Cast or forged!" Or in Dutch expressed, "cast or forged!". That's right - 2 correct answers, one is unfortunately still missing. After reading the texts below you will be a real wheel guru!

Cast wheels

The majority of wheels are manufactured this way. But also here we can divide the process into 2 ways: 'gravity casting' and 'low pressure casting'. In both ways we start by melting an aluminum alloy. In gravity casting the molten aluminum is poured into a mold and in low pressure casting the aluminum is injected from the bottom of the mold and filled low so that the chance of air bubbles is significantly less than in gravity casting. This also greatly reduces the chance of porosity in the wheel. In the modern industry, the two methods differ very little in strength due to the technologies available today.

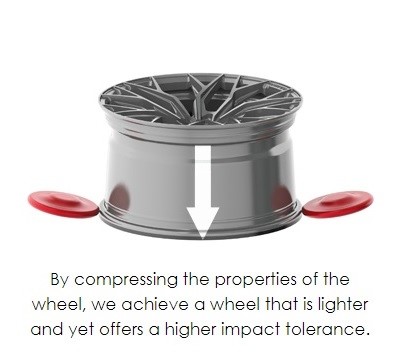

Flow Forming, Flowforging, Wheelrolling, Hybrid Forged

This technique begins with a pre-cast wheel that is mounted in a machine that uses hydraulic presses to roll out the wheel to its final shape and width. By applying these rolling and pressing techniques to a pre-cast wheel, the properties of the aluminum are greatly improved. The aluminum is re-textured and therefore has a higher strength and stiffness than its cast counterpart. Despite that the wheel is stiffer, by pressing and rolling the elasticity of the wheel increases. This allows the wheel to flex further before it will break. Because Flow Forming rolls out a pre-cast wheel, a narrower and therefore lighter pre-cast wheel can be used to arrive at the same specifications of a cast wheel. As a result, the same wheel size in a flow formed version will be 25% lighter and stronger than the cast version. This is a huge gain for weight which is at the extreme point of centrifugal force and therefore has the most effect!

Forged

The cream of the crop, the crème de la crème. Forged wheels are the top of the line when it comes to aluminum wheels. We would like to emphasize "aluminum" wheels here because there are still several possibilities when it comes to manufacturing wheels. For example, Koenigsegg offers its customers the option to choose "Aircore" carbon wheels.

Also in this classification there are multiple processes to obtain the final product. Machine forging (Machine forging) is the cutting of the wheel from one solid block of forged aluminum. This is done using a CNC Machine and is the most commonly used form for making forged wheels by producers of aesthetic and/or fashion wheels. With a machine forged forged wheel, the wheel is dependent on the direction and structure of the block of aluminum the wheel is made from. This is what makes mold form forging so superior to machine forging. Read why below.

Our final and most complex point: Mold-form Forging. In this process, a solid block of forged aluminum is pressed between two molds to create a basic wheel. By pressing an already forged block, the aluminum has an even higher density and the "grain structure" of the wheel has the direction of the wheel shape which gives enormous advantages in strength and stretchability. As a result, a forged wheel also requires less material to achieve the same target specifications as a cast wheel in the same dimensions. As icing on the cake, the newly pressed wheel undergoes another rolling process, which we saw earlier with the Flow Forming wheels, to extract even more weight from an already exceptionally light and strong wheel.